FERROABRATOR

ABRASIVES & BLASTING EQUIPMENT

Your high quality steel products deserve the high quality finish, our advanced Shot Blasting System makes possible. Ferroabrator is engineered to handle blasting away surface contamination, rust, scale and other impurities.

This blasting system leaves behind a smooth, clean surface on steel products surfaces, angles, parts or components that’s consistent with the ISO9001 standard and ready for assembly or painting.

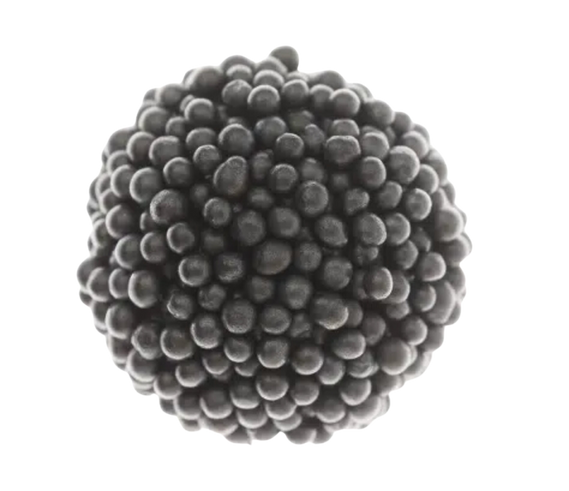

Our steel shot, manufactured under strict conditions and a unique tempering process, allows you to obtain a high carbon cast abrasive shot with optimal resilience, low chlorides & conductivity and high fatigue resistance. Used mainly in shot blasting applications, from desanding in foundries to descaling in steel mills, our HC steel shot will meet your most demanding needs.

GRADE | Size in mm |

S 70 | 0.125 – 0.425 |

S 110 | 0.180 – 0.600 |

S 170 | 0.355 – 0.850 |

S 230 | 0.500 – 1.000 |

S 280 | 0.600 – 1.180 |

S 330 | 0.710 – 1.400 |

S 390 | 0.850 – 1.700 |

S 460 | 1.000 – 2.000 |

S 550 | 0.180 – 2.000 |

S 660 | 1.400 – 2.360 |

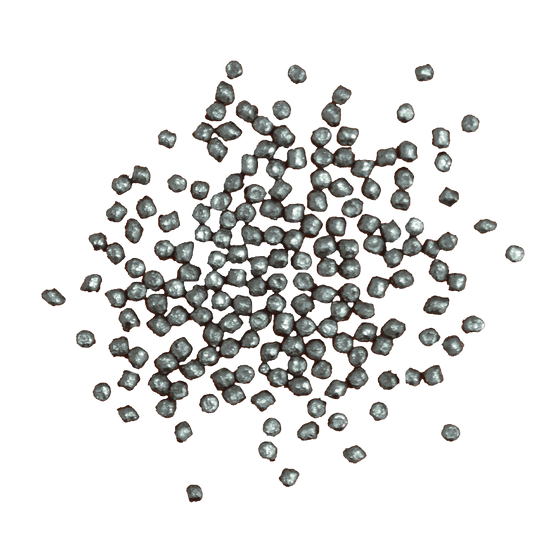

Steel grit blasting abrasive, high carbon, cast, manufactured under strict quality controls and conditions, using a unique air quenching thermal process, which will deliver a long lasting media. With minimal chloride & salt concentration, you receive a blasting media with the highest impact value for your cleaning application. Used primarily in blasting for surface preparation prior to painting, it is also used for descaling and desanding applications.

GRADE | Size in mm |

G 12 | 1.400 – 2.360 |

G 14 | 1.180 – 2.000 |

G 16 | 1.000 – 1.700 |

G 18 | 0.710 – 1.400 |

G 25 | 0.425 – 1.1800 |

G 40 | 0.300 – 1.000 |

G 50 | 0.180 – 0.710 |

G 80 | 0.125 – 0.425 |

G 120 | 0.075 – 0.300 |

Get in touch with us.

info@ferroabrator.com